Kang Deli was invited to attend the 4th General Assembly of the China Soybean Industry Association and quietly showcased its leading advantages in frame-type cable wiring without sheathing.

Release time:

2025/12/02

On December 2, 2025, the 4th General Assembly of the China Soybean Industry Association and the 1st Meeting of the 4th Council were solemnly held at Beidahuang Agricultural Reclamation Group Co., Ltd. As a member unit of the Association’s council, Kangdeli was invited to attend the meeting, where it joined industry leaders, experts, and scholars from across the country to discuss new opportunities for industry development and jointly explore new pathways for high-quality growth. This conference focused on the core issues of revitalizing the soybean industry, clearly defining key development directions such as variety research and development, industrial chain upgrading, and industry-wide collaboration. These efforts lay a solid foundation for enhancing the quality and efficiency of China’s domestic soybean industry and strengthening the nation’s food security barrier.

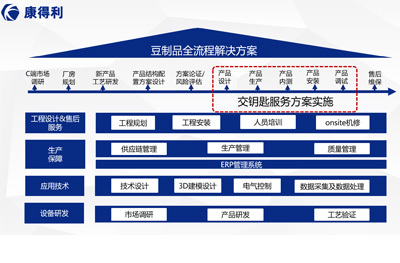

Kangdeli Enterprises deeply resonates with the “whole-industry-chain collaborative upgrading” concept proposed at the conference. For many years, we have been deeply engaged in the field of advanced soybean processing equipment, using technological innovation as our driving force to help the soybean industry transform toward greater efficiency, environmental sustainability, and higher value-added production. As a member of the association’s board of directors, Kangdeli representatives thoroughly studied the conference’s directives on high-quality development of the soybean industry during the meeting. At the same time, drawing on our own practical experience in the field of advanced soybean processing equipment, we shared and discussed our independently developed frozen tofu production line technology with colleagues from across the industry.

The box-type, bagless tofu production line at Harbin Beidahuang Bean Products Co., Ltd., which members visited this time, is a highly automated piece of equipment independently developed and stably operated by Kondeli. This technology was first pioneered in Japan. After years of intensive technical research and continuous iterative upgrades, Kondeli has achieved the industry’s first domestically produced alternative equipment solution, which has been running smoothly for over two years. This bagless tofu production line is specially designed for deep-processing soybean enterprises and boasts seven outstanding features:

1. The innovative bagless design eliminates the drawbacks of traditional production methods, such as high consumption of packaging materials and the need for manual labor, significantly improving operational cost-effectiveness and helping enterprises reduce costs while boosting efficiency.

2. It can simultaneously produce products such as firm tofu, frozen tofu, and soft tofu.

3. The automation level is industry-leading, enabling fully unmanned operation throughout the entire process—from bean curd pouring and pressing to shaping and boxing—significantly reducing labor input and lowering management costs.

4. Equipped with an automatic mold-cleaning system, the process involves multiple steps—soaking in alkali, washing, and spraying—to thoroughly remove residual impurities, inhibit microbial growth, and effectively extend the shelf life of tofu.

5. The product boasts high forming accuracy, with neatly squared edges and corners on the tofu and a uniformly smooth surface. After being cut into pieces and packed into boxes, the weights are highly consistent, eliminating the need to leave extra margins—directly boosting the company’s economic efficiency.

6. The in-situ storage design is convenient and efficient; after cleaning, the mold boxes can be left in place on the production line, significantly reducing machine start-up and shut-down times and enhancing production continuity.

7. Equipped with a dedicated yellow slurry collection tank to promptly collect production wastewater, keeping the workshop environment clean and helping enterprises achieve standardized and hygienic production management.

After two years of stable operation of this equipment, Kangdeli has recently been focusing on promoting this production line. We’ve successfully established procurement partnerships with two new customers, and installation and commissioning are scheduled to begin by the end of this year. It’s precisely the trust our customers have placed in us that continues to fuel our drive forward. As a leading enterprise integrating R&D, design, manufacturing, and training for modern soybean product and plant-based beverage processing equipment, Kangdeli will remain deeply committed to advancing the automation and modernization of production lines. With more advanced technologies, more reliable equipment, and even better services, we’ll empower deep-processing soybean enterprises and join forces with colleagues across the industry to jointly expand the value potential of the soybean sector, making a solid contribution to the revitalization of China’s soybean industry!

For more details on automated tofu production lines and plant-based beverage production lines, or to explore customized solutions, please visit our company website for inquiries and discussions. Our contact number is 0573-87876868. Let’s embark together on a new journey of industrial development!

Key words:

Previous Page

Previous Page