Solution

2024

Make a soy milk product that will satisfy consumers, Our advice is to understand the process technology and use the right equipment.

2024

In response to this bottleneck and problem encountered by the product, soy milk products with zero addition of food additives, good stability and long shelf life have appeared on the market in recent years. This is mainly achieved through advanced production technology and equipment.

2024

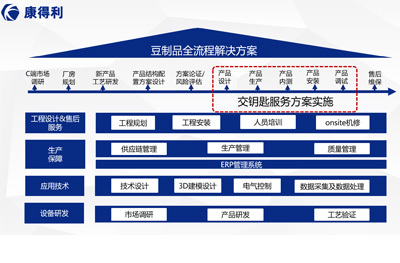

The turnkey project is the guarantee of the engineering construction of Kangdali Intelligent Technology Co., Ltd. We will undertake a series of engineering construction processes including equipment installation, commissioning and smooth operation of preliminary operations, and "hand over" the "key" of the ownership and management of the factory and project to you in accordance with the contract. You can start production and operation activities immediately after you get the "key.

Products

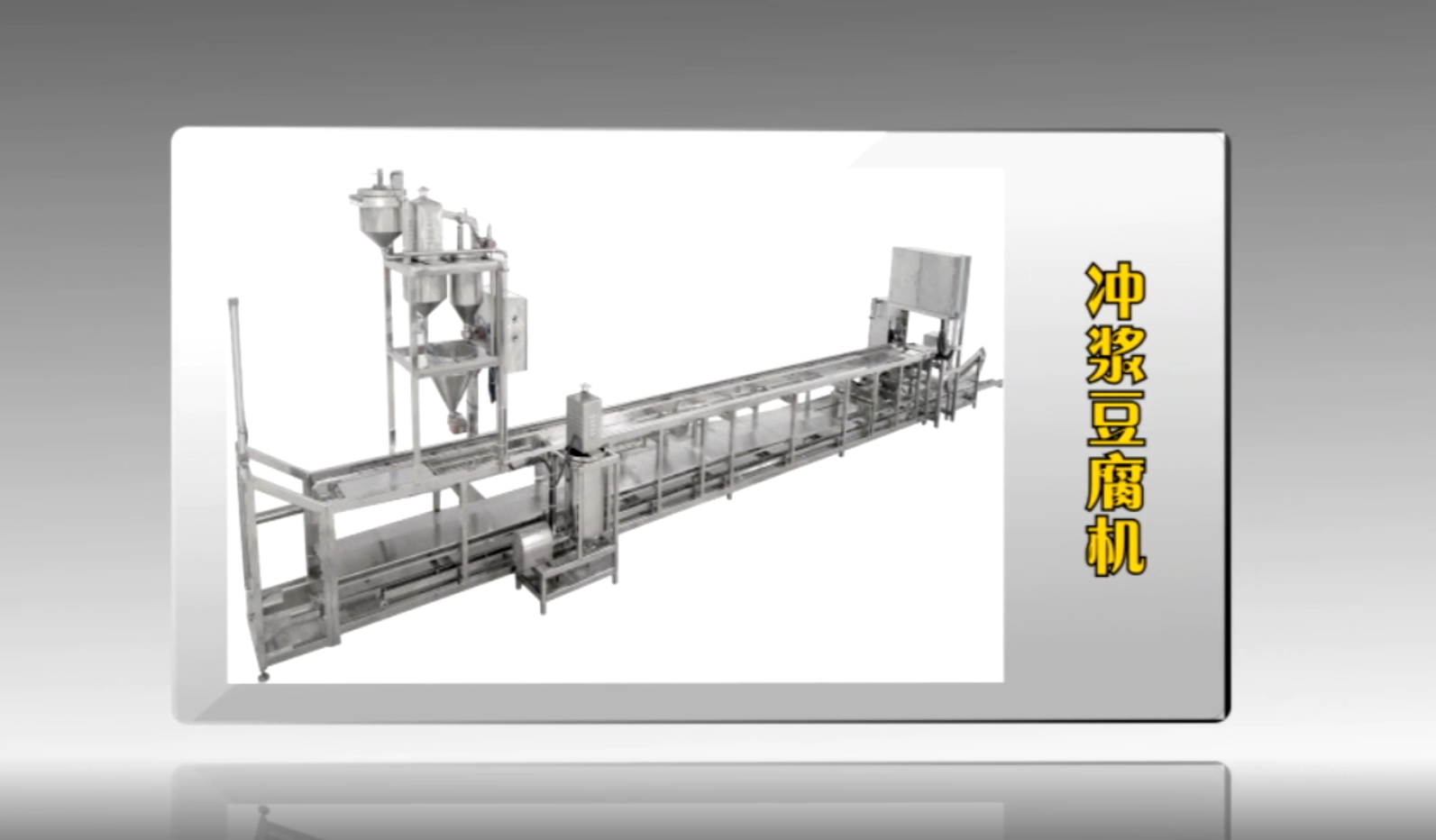

Old tofu automatic production line equipment

This set of automated old tofu production solution is mainly equipped with bean soaking system, grinding system, separation system, boiling system, pulp pressing and cutting packaging system. The dry bean processing capacity is 100 to 500kg/hour. With the coagulation equipment design of Kangdeli food machinery, the tofu production line can produce natural standard tofu at 25 to 135 plates of tofu/hour, while the weight of each plate of tofu is about 10kg.

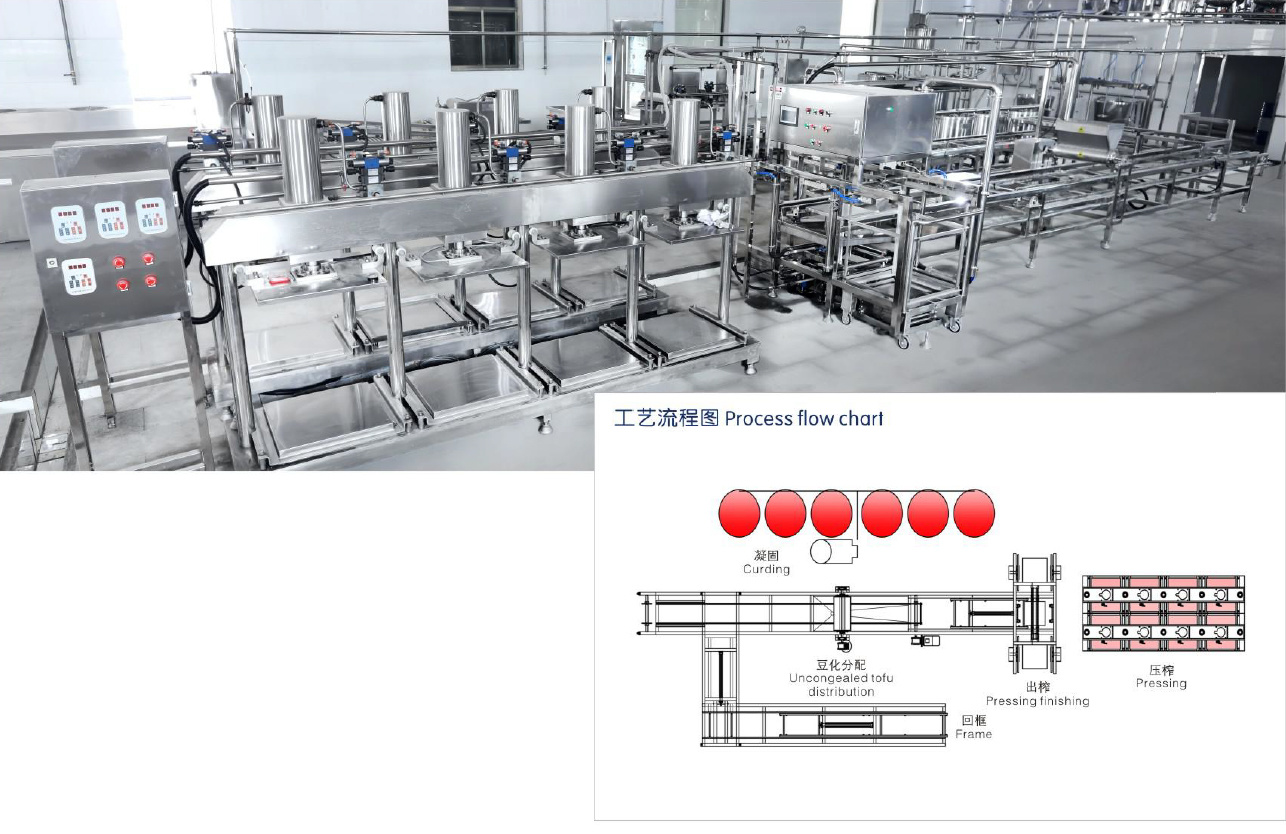

Learn moreTender tofu automatic production line equipment

In the face of the growing demand for tofu in the market, many tofu makers began to seek ways to expand production capacity and increase sales profits. Considering the rich nutritional value of old tofu, such as its effect of controlling sterols, lowering blood pressure and protecting cardiovascular system, as well as the benefits of unsaturated fatty acids and rich lecithin on improving blood vessel elasticity and memory, the market demand for tofu continues to rise. This automated production line is designed to help tofu makers solve the problems of manpower shortage, production control difficulties and product quality instability.

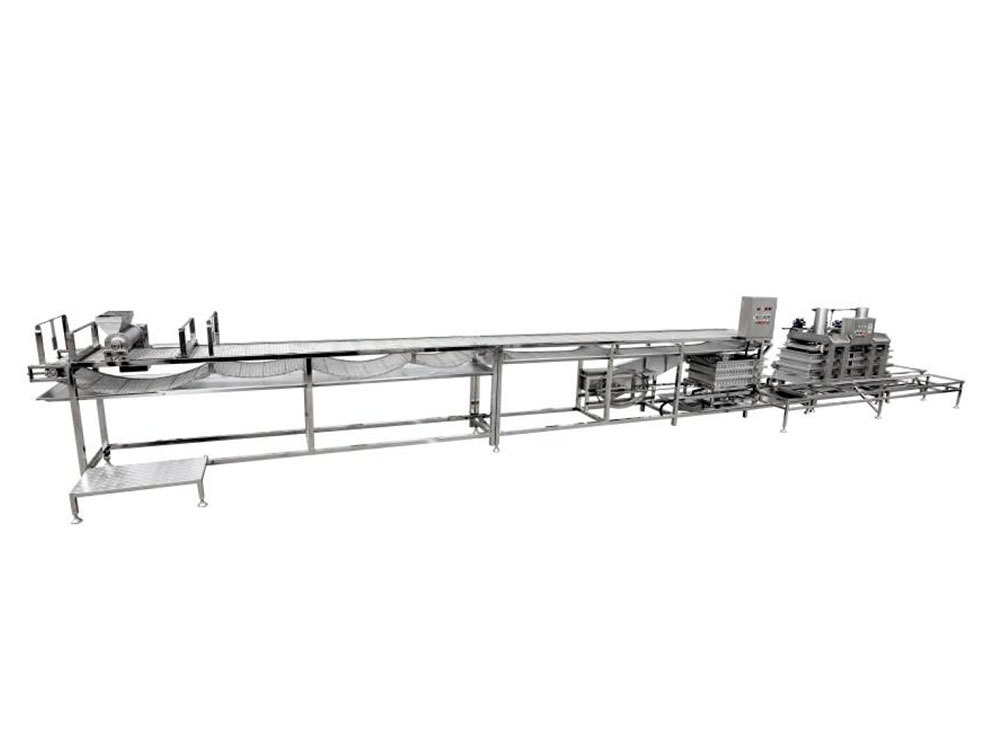

Learn moreDry bean automatic production line equipment

This fully automated dry bean production line is an efficient production solution, covering the whole process from raw material processing to finished product packaging. It is mainly composed of several key parts: the soaking system for soaking beans, the grinding system for grinding beans to extract slurry, the separation system for separating soybean dregs and soybean milk, the boiling system for boiling soybean milk, and the final point pulp, pressing, Cutting and packaging systems. The dry bean processing capacity of this system is between 400 and 600kg per hour. With the high-efficiency coagulation equipment of Yongsmooth Food Machinery, it can produce natural standard tofu of 200 to 300 plates per hour.

Learn moreSufu automatic production line equipment

This fully automated fermented bean curd production line is an efficient production solution, covering the whole process from raw material processing to finished product packaging. It is mainly composed of several key parts: the soaking system for soaking beans, the grinding system for grinding beans to extract slurry, the separation system for separating soybean dregs and soybean milk, the boiling system for boiling soybean milk, and the final point pulp, pressing, Cutting and packaging systems. This system has a dry bean processing capacity of between 400 and 700kg per hour. With the high-efficiency coagulation equipment of Condley Food Machinery, it can produce natural standard tofu of 100 to 300 plates per hour.

Learn moreABOUT US

BEIJING KINGDLEY INTELLIGENT TECHNOLOGY CO., LTD

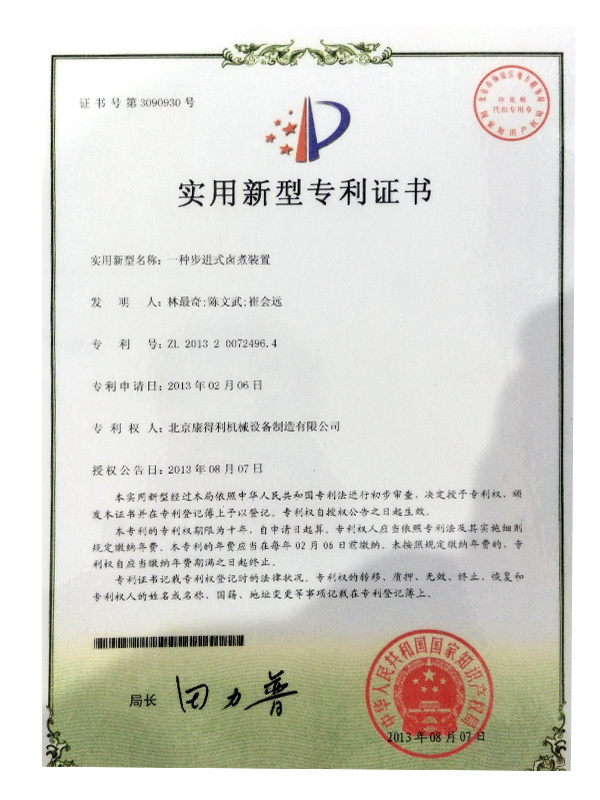

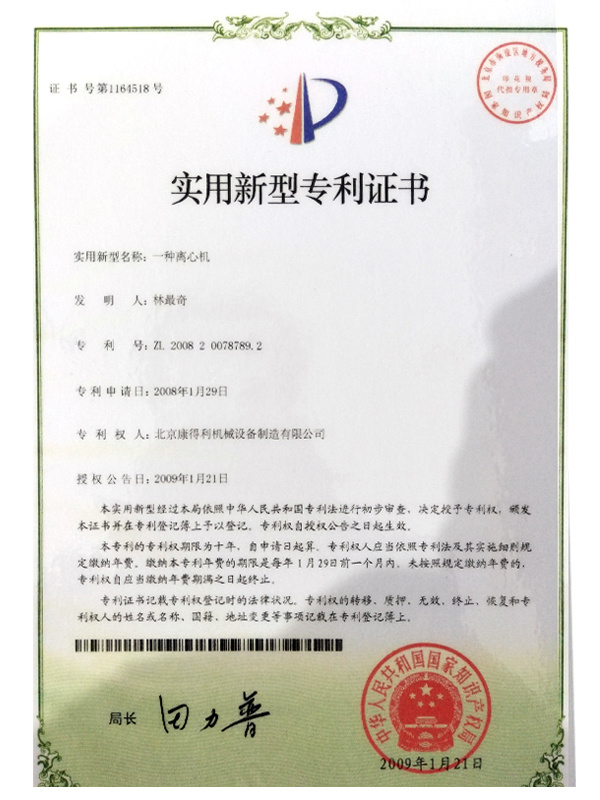

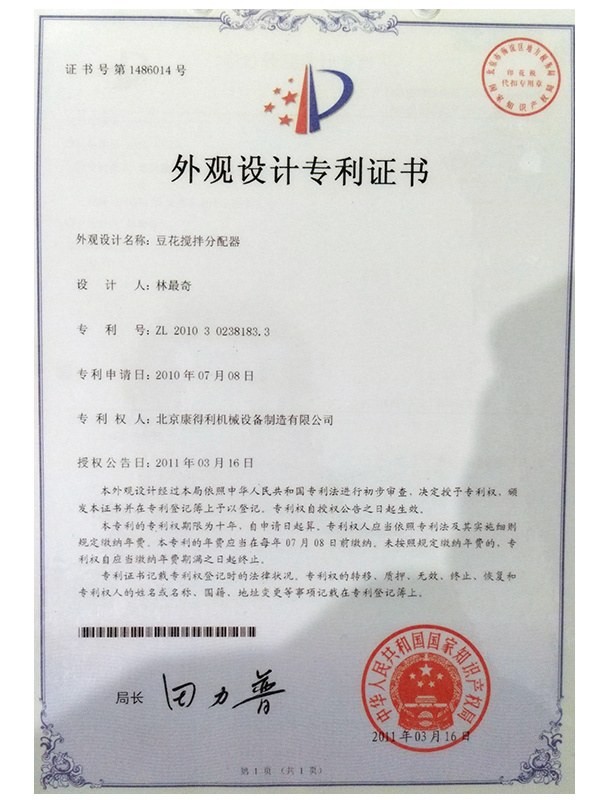

Kangdeli Intelligent Technology Co., Ltd. was established in Beijing in 1996 and is now located in Jianshan New District, Haining, Jiaxing City, Zhejiang Province. It is a high-tech enterprise focusing on intelligent manufacturing of plant-based equipment such as soybeans and oats.

The company has developed a variety of types of products, providing complete sets of intelligent equipment and comprehensive solutions for the bean products and plant protein beverage industry, and is committed to continuously improving the level of technical equipment for bean products and plant-based beverages, filling the gaps in the industry and leading the development of the industry.

Time of establishment

Registered capital

On-the-job staff

Qualification Certificate

NEWS

2025/12/02

2016/10/26