2024/06/03

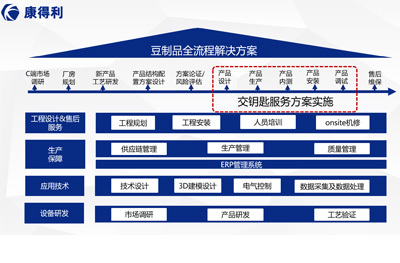

As the second stage of the turnkey engineering process, we will carry out the production of products according to the requirements of the contract. We have a professional quality inspection department to ensure that the products produced from our factory are strictly inspected, and our products will be tested before delivery.

Installation and commissioning phase

2024/06/03

This phase is the final stage of the turnkey project, that is, the commissioning, commissioning, and put into operation of hardware and software. Kangdeli has a strong on-site strain and processing capacity, can fully ensure that the project can be completed on time, so that you can carry out production and business activities faster.

2024/06/03

In the long-term practice, Kangdeli has built a strong technical team by introducing talents, cultivating talents, and cooperating with universities. Among them, there are more than 20 technical research personnel with graduate students as the main body. The company has successfully developed the technology of no-single badge pressing domestic dishes, unattended full-automatic soybean milk production line, full-automatic raw and cooked pulp free switching system, sour water bean magic automatic solidification system, water-filled bean opera (bean flower) processing production line, pulp bean curd processing production line, oil bean curd processing production line, and non-cloth molding technology vegetable acid soybean milk processing technology and equipment.

Using our machinery to make tofu will be a breeze

2024/05/14

Tofu is a kind of nutritious and long-standing food. The public's love for tofu has promoted the progress and development of tofu making technology. Tofu contains a variety of essential trace elements, but also rich in high-quality protein, known as "plant meat" laudatory name. The digestion and absorption rate of tofu is more than 95%. Such healthy food has always been loved by everyone. However, if we want to give full play to the nutritional value of tofu, we need to pay attention to the matching. The tofu making process includes washing beans, soaking beans, grinding, boiling, ordering and pressing. You don't have to work hard to make tofu by hand with our machine. Automatic operation makes it easy and labor-saving to make a large amount of tofu.

Multiple technologies and equipment

2024/06/03

The company has successively reached long-term cooperation with Zengxing Machinery, MU YASUJIMA Co., Ltd., Japan LANDSWNORK and other enterprises, and successfully introduced and developed a number of technologies and equipment.

2024/05/14

As the initial stage of the turnkey engineering process, we will design the products according to the customer's requirements. Our pre-sales engineering department will make the equipment list and material list according to your requirements, and our technical department will also develop and design the equipment according to your requirements.