Share

Pulping Integration (raw pulp process)

View similar products

Label List

- Product Description

-

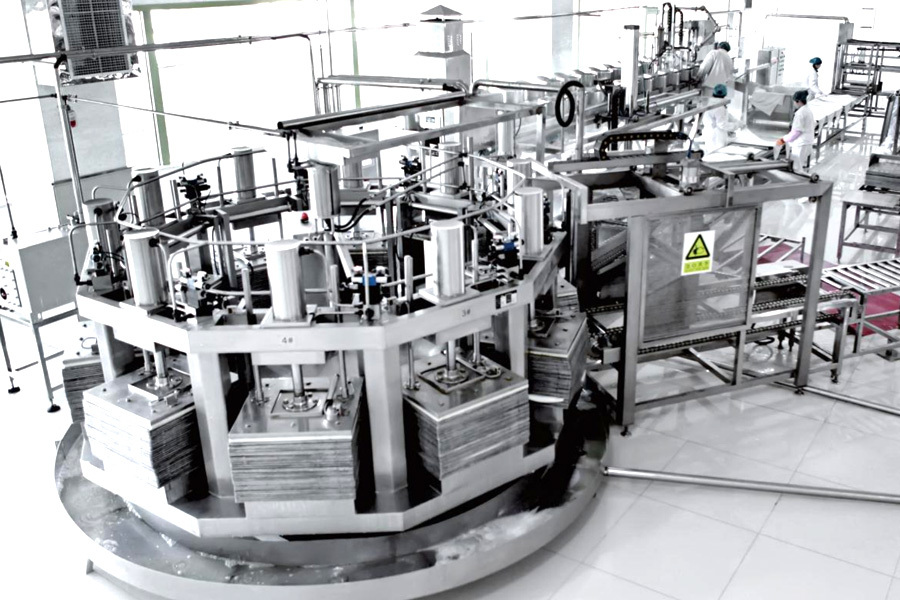

With the transformation of business models, many small factories are becoming more and more efficient. Although traditional tofu production equipment meets their needs for small output and low cost, it has fatal shortcomings: low efficiency and unstable quality. After market research, Kangdeli came up with the invention of an integrated equipment integrating grinding and boiling: raw pulping and pulping integration. This equipment not only reduces the labor cost of producers, but also greatly increases the production efficiency of producers. The finished soybean milk and bean curd products are mellow and rich, which is definitely a very good choice for exhibition shops or small factories.

Features:

1, automatic lifting wet beans, low labor intensity;

2, water bean quantitative distribution, soybean milk concentration can be controlled;

3, negative pressure suction, eliminate soy milk foam;

4. Closed micro-pressure boiling pulp, good taste.

Specifications and models

Model

ZJJC-1000-R-101

ZUC-2000-R-101

production capacity

80-100 kg/h (dry beans)

Rated voltage

3N-380V

Rated power

8.97KW

Overall dimension

2500 × 1200 × 3000mm

Pulping Integration (raw pulp process)

View similar products

Label List

Product inquiry

Note: Please leave your mobile phone and email address, our professionals will contact you as soon as possible!