Share

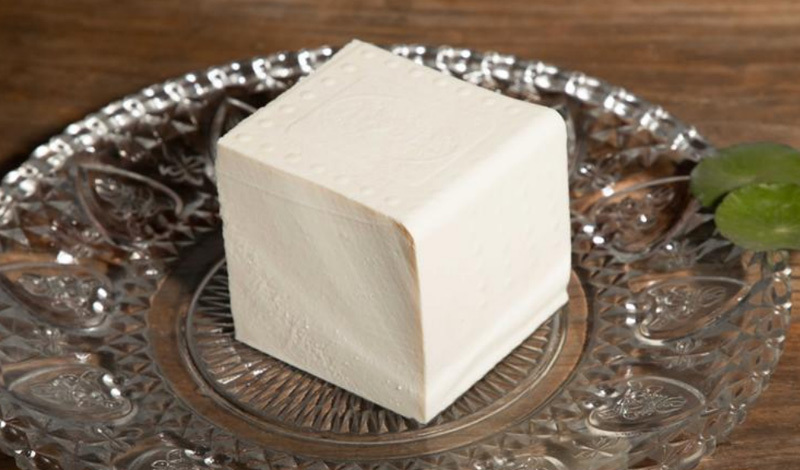

Tender tofu automatic production line equipment

View similar products

Label List

- Product Description

-

1. soft tofu automatic production line equipment introduction

In the face of the growing demand for tofu in the market, many tofu makers began to seek ways to expand production capacity and increase sales profits. Considering the rich nutritional value of old tofu, such as its effect of controlling sterols, lowering blood pressure and protecting cardiovascular system, as well as the benefits of unsaturated fatty acids and rich lecithin on improving blood vessel elasticity and memory, the market demand for tofu continues to rise. This automated production line is designed to help tofu makers solve the problems of manpower shortage, production control difficulties and product quality instability.

Intelligent control to reduce labor costs, optimize production capacity]

The old tofu production line of Kangderi Intelligent Technology realizes the automatic control of the production process by adopting PLC (programmable logic controller) and HMI (human machine interface) technology. This not only reduces the dependence on skilled operators and reduces labor costs, but also simplifies the operation process so that any operator can easily get started, and the steps from the placement of the tofu mold to the squeezing of the tofu block can be completed efficiently. In addition, the remote upgrade function of PLC and HMI ensures the easy maintenance of the equipment and the long-term stable operation of the system, making tofu production simple and efficient. Through this system, tofu makers can easily increase production capacity and ensure product quality, so as to meet the high demand of the market.

[One click, tofu production is no longer difficult]]

Kondeli Machinery uses intelligent technology to control every step and parameter of the tofu making process to ensure consistently high-quality results. Through a simple and easy-to-understand operation interface, we can make tofu after simple training, and the training time is only three days. Using our equipment, tofu production is no longer difficult!

We teach you how to make good tofu simply]

If you have never made tofu in the past and want to enter the tofu industry; produce your first piece of tofu, please feel free to give it to us! We provide complete production equipment as well as technology transfer. You no longer need to spend several years learning how to make tofu, wasting your precious time and thus unable to successfully grasp the market opportunities. We have teachers who have been deeply engaged in the bean products industry for more than 20 years to teach you how to make tofu. With the fastest time to join the tofu industry, the production of high quality tofu, will be the key to your investment success!

1. Pre-processing system

1. Mainly includes dry bean conveying system and soaking system. The soaking system is mainly based on the subsequent product types and output to choose different sizes and quantities of bubble bean barrels, production line characteristics;

2. The machinery produced by Kangdeli Intelligent Technology Co., Ltd. has quantitative equipment, which can accurately weigh dry beans to ensure product stability;

3. Timing automatic into, drainage, in saving labor costs at the same time to ensure that the high level of soaking beans;

4. Turn beans automatically at regular intervals to ensure that all soybeans can be soaked evenly, improve the extraction rate of soybean protein, change water and cut off power, alarm for water shortage, and solve potential safety hazards;

5. We pay great attention to the soaking quality of soybeans at the beginning of each step, automatically adjust the water temperature, fully automated, and save labor costs.

2. Wet bean quantitative lifting system

1. It integrates the functions of wet bean draining, cleaning and quantitative conveying, and the integrated equipment saves the floor space and reduces the equipment cost;

2. The equipment uses the principle of screw conveying to ensure the stability of the conveying rate of soybeans;

3. Low energy consumption, strong adaptability, reasonable equipment size design, low requirements for plant height.

3. Pulping system

1. Kondley equipment accurately controls the concentration of soybean milk, accurately quantifies the soybean water supply, accurately controls the concentration of soybean milk (within 0.5 Brix), and brings high quality with high precision;

2. The protein extraction rate is high, and the residue of soybean protein is less than 2.5% (wet basis);

3. Shorten the raw pulp oxidation time, reduce the raw pulp foam through the grinding equipment to obtain the product foam does not affect the next step of work;

4. Easy to operate, saving labor;

5. The concentration is automatically adjusted online, and the concentration of soybean milk is accurately controlled by accurately regulating the ratio of material to water.

4. Slagging system

1. The centrifuge produced by Kangdeli has a good slag removal effect, with low moisture content and high protein extraction rate.

2. Easy to clean, can access CIP, through the CIP to clean the centrifuge can effectively reduce labor costs

3. You can choose different types, and the machine is suitable for various production scenarios, and can ensure long-term high-intensity operation without problems

4. There is a stainless steel filter screen inside, which has a long service life, and the filter screen can guarantee that it does not need to be replaced within 1 year.

5. Boiling pulp system

1. Menu-style selection of boiling pulp mode, automatic control of steam and pulp mixing ratio; physical defoaming. No need to use defoaming agent;

2. Soybean milk (bean dregs are separated after being ground with water). Bean paste (bean dregs are not separated after being ground with water) can be boiled;

3. The bad gas can be discharged during the cooking process to ensure safety and ensure that the internal pressure is within a safe range;

4. CIP cleaning to ensure food hygiene and safety, optional heat recovery system.

6, point slurry system

1. The pulping and solidification machine can take into account different types of coagulants. The design process takes into account the different mechanisms and dosages of various coagulants in tofu molding, and can flexibly adjust the parameters such as stirring mode and solidification time. On the premise of retaining and inheriting the advantages of traditional artificial point pulp, the realization of intelligence, automation and mechanization can improve the economic benefits of customers while improving production efficiency.

2. Simulate manual pulping to ensure that the coagulant and soybean milk can be fully mixed.

3. Without vibration transmission, tofu brain will not be greatly affected by equipment operation, and squatting brain effect is good.

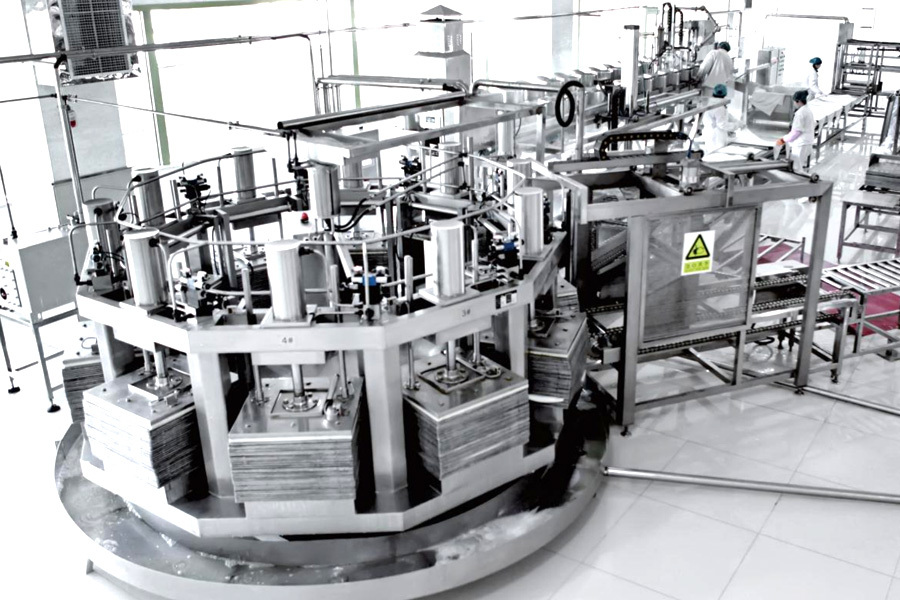

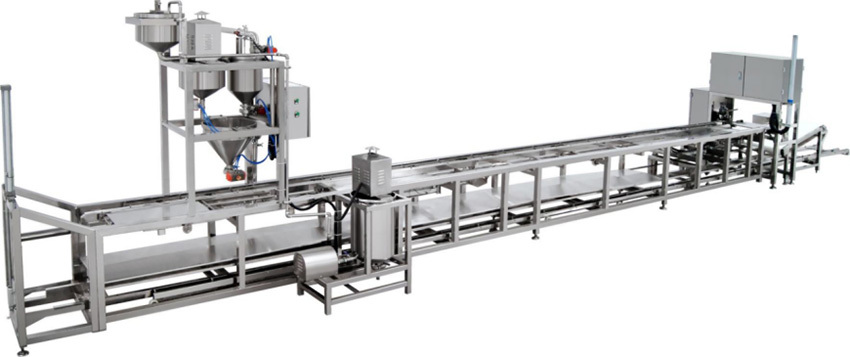

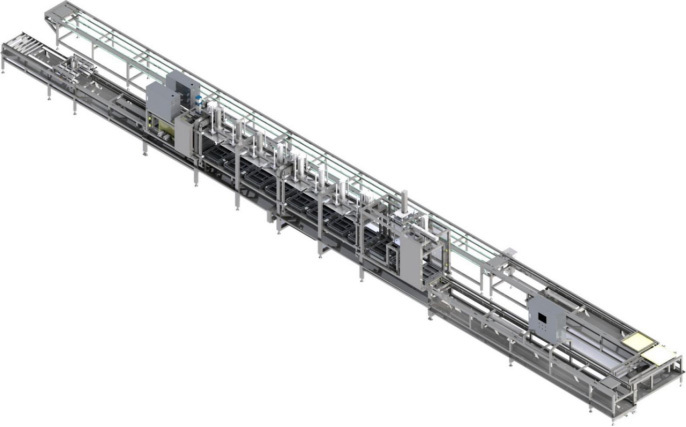

7. Tofu production system

including the pressing form of a stepping press;

1. Supporting automatic cutting, packaging, sterilization equipment can complete automatic cutting box, packaging sealing, tofu box trimming, pasteurization and other functions;

2. available brine, acid slurry and other coagulant automatic point slurry;

3. Continuous and gradual pressure, good tofu forming effect;

4. Suitable for plate tofu, box tofu and other types of products.

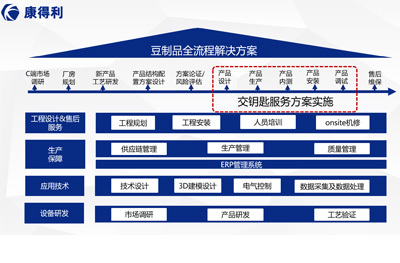

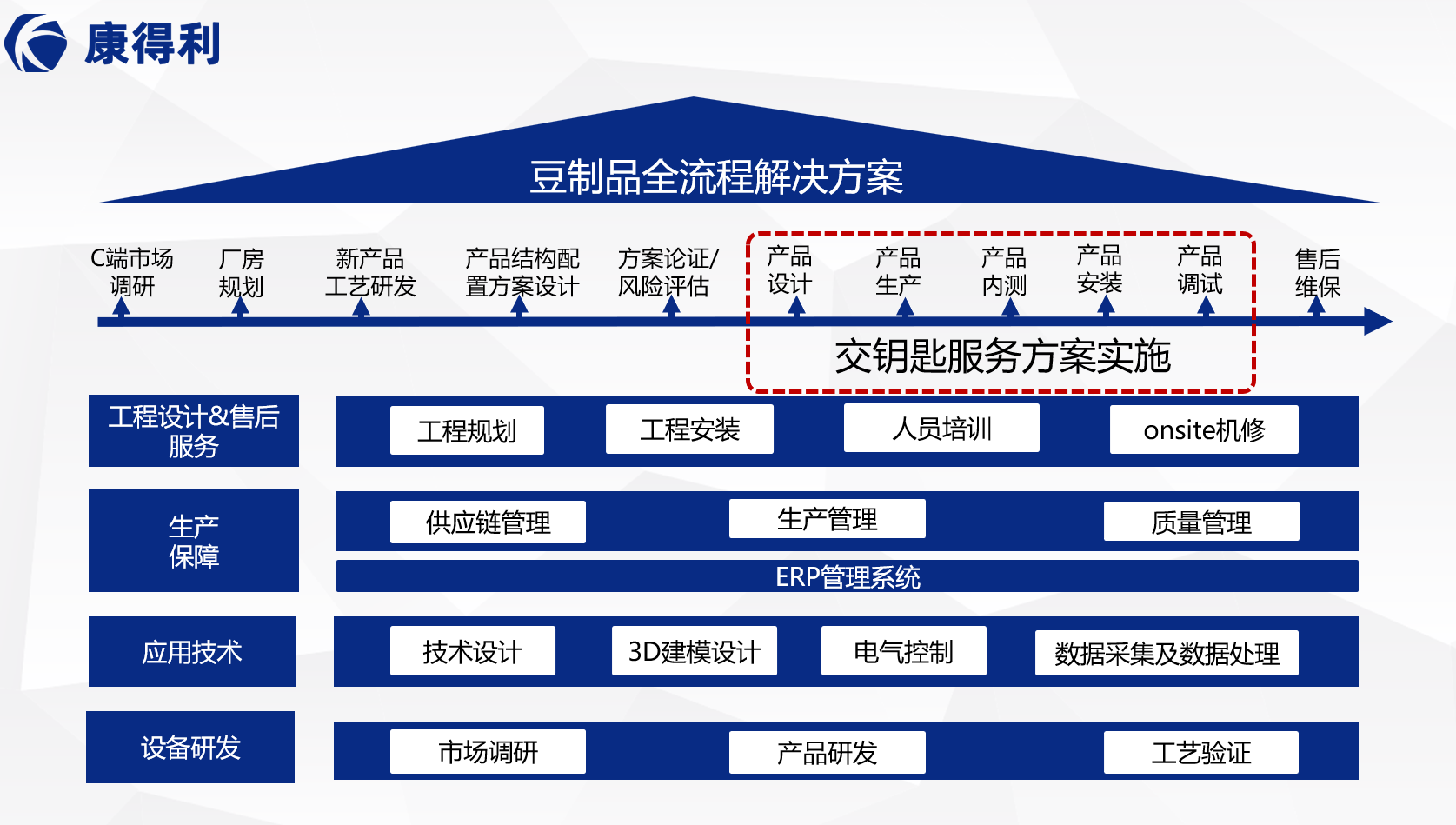

Full process solution

We have professional marketing. R & D. Pre-sales. After-sales team, to provide you with professional bean products full process solutions.

Service Consulting

Kondley Intelligent Technology provides 24-hour online consultation, cooperates with engineers, solves customer problems through remote operation, saves round-trip time and labor costs, and can quickly solve customer problems. In addition, for food equipment companies that have just started a business or expanded their factories, our engineers will visit the company's site to help you plan the layout. In the past 28 years, we have established good cooperation with global customers such as Sweden/Malaysia/USA/Indonesia/Canada, and passed on the technical know-how of producing soybean milk and tofu to our customers. We are committed to being the leading solution provider.

Consulting Services

Please contact us and we will provide you with further consulting services.

Tender tofu automatic production line equipment

View similar products

Label List

Product inquiry

Note: Please leave your mobile phone and email address, our professionals will contact you as soon as possible!