Share

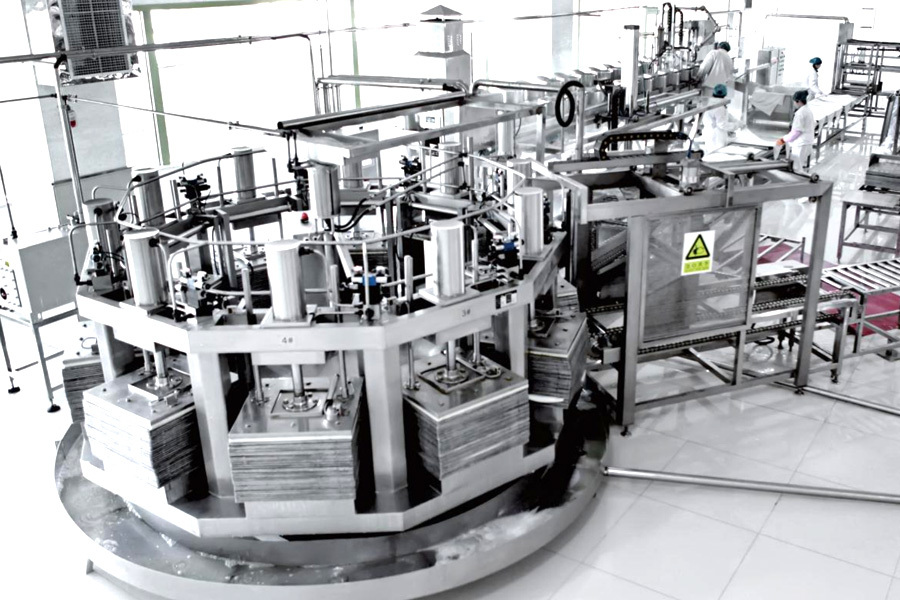

Horizontal spiral centrifuge

View similar products

Label List

- Product Description

-

The soybean milk and soybean dregs are separated by a spiral extrusion separator to obtain the soybean milk from which the soybean dregs are removed.

1. Applicable objects of this type of equipment:

A single horizontal spiral extrusion separator equipment has a large output, suitable for large factories for batch production, and the centrifuge can be applied to the cooked pulp process and raw pulp process, and the separated soybean milk particle size D90 is less than 10 microns, the product is more expensive to use but suitable for the production of soybean milk beverages.

2. The main differences between different models of separation equipment-size and output:

The spiral extrusion separator is divided into three models according to the output and size. Different sizes and models can be used in different production scenarios.

3. Easy to clean and maintain:

The design is reasonable, the internal structure is simple and easy to clean, and the adjustment is convenient. And after long-term use will not be due to rust or oxidation of the whole machine scrapped.

4. Before leaving the factory, each horizontal spiral extrusion separator must be tested by a special person.

We have a complete resume tracking system, and each horizontal spiral extrusion separator is equipped with a running water number for subsequent tracking inspection. At the same time, each spiral extrusion separator machine has a special person to carry out actual testing to ensure that it can be operated and flawless before it can be shipped.

Features:

1, the removal efficiency is high, can effectively separate the bean dregs from the soybean milk (bean paste).

2. The equipment has simple structure and convenient operation and maintenance.

3. High separation factor, good separation effect and large production capacity.

4. Long service life and convenient cleaning.

Specifications and modelsModel

LWG364

LWG434

LWG554

production capacity

2-3m3/h

5-6m3/h

8-10m3/h

Rated voltage

3N~380V

3N~380V

3N~380V

Rated power

15kW 5.5kW

30kW 7.5kW

45kW 11kW

Overall dimension

3170 × 1000 × 1220mm

3600 × 1140 × 1310mm

4880 × 1580 × 1540mm

Cuisine Application

It can be used to separate soybean dregs in soybean milk and make soybean products and soybean milk by using the dregs-off soybean milk.

Kangdeli business team to provide 24 hours of online consultation response and after-sales service, has provided a quick way to solve the problems encountered by customers, to customers the most complete service. Want to know more information welcome to come to consult, we will provide the past experience of counseling customers, give you the most complete advice.

Horizontal spiral centrifuge

View similar products

Label List

Product inquiry

Note: Please leave your mobile phone and email address, our professionals will contact you as soon as possible!