Share

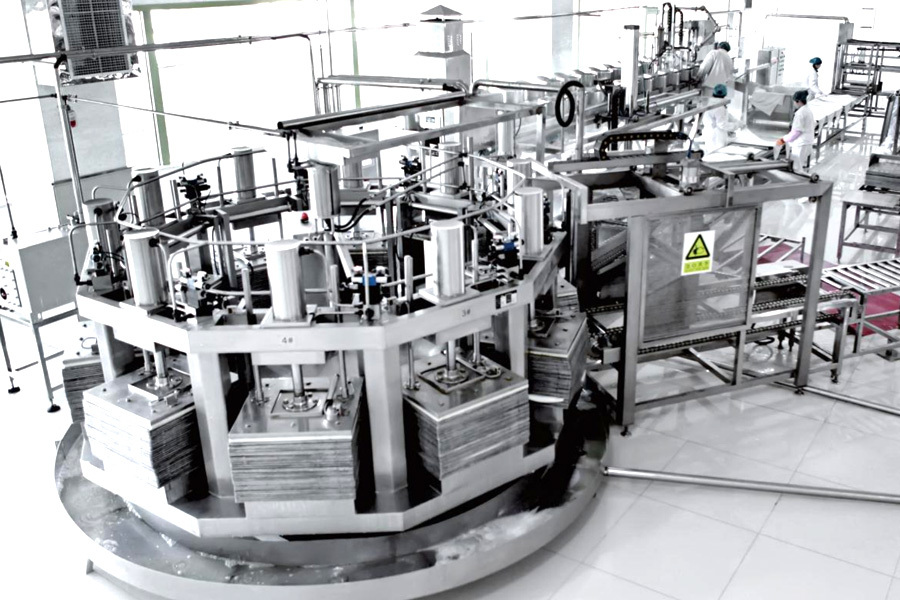

Oat milk automatic production line equipment

View similar products

Label List

- Product Description

-

1. Oat Milk Automatic Production Line Equipment Introduction

Oat milk is not actually milk, the reason is called oat "milk", just because its color and milk is very similar. In fact, it is a grain beverage made of "oat water", which is made from oats and processed through an extraction process, which means that it is not a dairy product or any animal by-product. Because oat milk is made from oats, a large number of natural nutrients-vitamins, minerals and micronutrients contained in oat milk will also be retained in oat milk. These substances are not only rich in dietary fiber and protein, but also include some trace elements, such as manganese, phosphorus, vitamin B1, folic acid, zinc, iron, selenium and copper.

Intelligent control to reduce labor costs, optimize production capacity]

The oat milk production line of Kondeli Intelligent Technology realizes the automatic control of the production process by adopting PLC (programmable logic controller) and HMI (human machine interface) technology. This not only reduces the dependence on skilled operators and reduces labor costs, but also simplifies the operation process so that any operator can easily get started. The remote upgrade function of PLC and HMI ensures the easy maintenance of the equipment and the long-term stable operation of the system, making oat milk production simple and efficient.

[One click, oat milk production is no longer difficult]]

Kondeli Machinery uses intelligent technology to control every step and parameter of the oat milk production process to ensure consistently high-quality results. Through a simple and easy-to-understand operation interface, we can allow production personnel to operate the equipment after simple training, and use our equipment to make the production of oat milk easier!

[We have a variety of oat milk production process, to provide you with high-quality process support]]

If you have never made soy milk in the past and want to enter the oat milk industry; Please feel free to give us your first bottle of soy milk! We provide complete production equipment as well as technology transfer. You no longer need to spend time to study the process, wasting your precious time, which will lead to the failure to successfully grasp the market opportunities. We have a professional R & D center to provide you with detailed, accurate and popular oat milk technology. With the fastest time to join the oat milk industry, the production of high quality soy milk products, will be the key to your investment success!

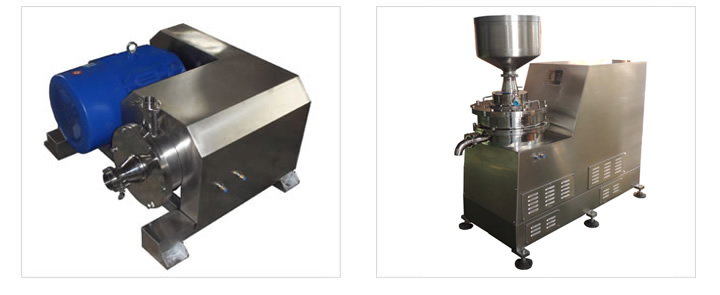

1. Pulping system

1. The new technology adopts the international advanced controlled cutting technology to control the crushing fineness of fiber materials within the set range, meeting the requirements of coarse, fine and ultra-fine wet crushing in production.

2. The new structure is cut and broken by comb-shaped stator. The fineness is determined by the density of the gap. The ultra-high linear speed suction impeller provides super cutting force, and the wet fiber crushing can reach 100 meshes.

3. More reliable use of integral mechanical seal to solve the high-speed operation of the material leakage and cooling medium pollution and other issues, easy to install and replace.

4. More stable use of optimized design concept, the effective integration of advanced technology and innovative thinking, and reflected in the specific

2. Enzymatic hydrolysis system

3. Enzyme inactivity system

1. Convenient assembly and disassembly, few seals, extremely low maintenance cost, high flow rate in the casing, delay scaling, and reduce intermediate cleaning.

And from the equipment cleaning, disinfection to the material processing, have PLC control system control and adjustment.

3. The temperature control coefficient adopts imported original.

4. Can be designed and manufactured according to customer requirements

4. Snail slag separation system

1, the removal efficiency is high, can effectively separate the bean dregs from the soybean milk (bean paste).

2. The equipment has simple structure and convenient operation and maintenance.

3. High separation factor, good separation effect and large production capacity.

4. Long service life and convenient cleaning.

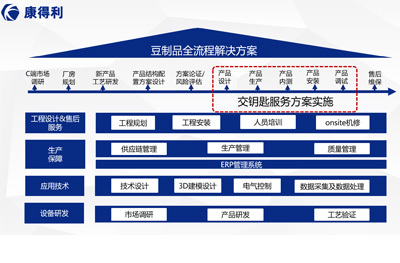

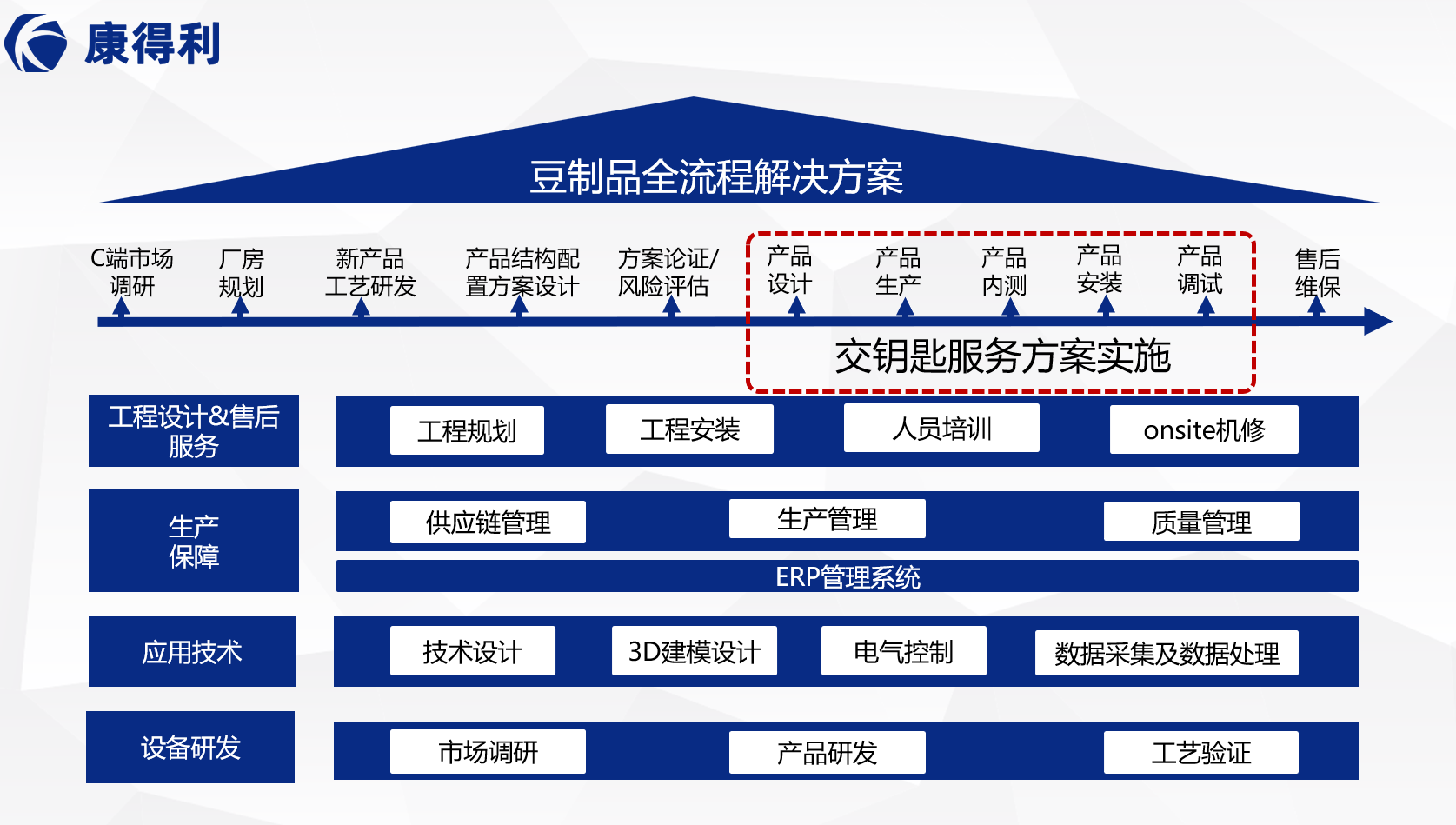

Full process solution

We have a professional marketing, research and development, pre-sales, after-sales team, to provide you with professional bean products full process solutions.

Service Consulting

Kondley Intelligent Technology provides 24-hour online consultation, cooperates with engineers, solves customer problems through remote operation, saves round-trip time and labor costs, and can quickly solve customer problems. In addition, for food equipment companies that have just started a business or expanded their factories, our engineers will visit the company's site to help you plan the layout. In the past 28 years, we have established good cooperation with global customers such as Sweden/Malaysia/USA/Indonesia/Canada, and passed on the technical know-how of producing soybean milk and tofu to our customers. We are committed to being the leading solution provider.

Consulting Services

Please contact us and we will provide you with further consulting services.

Oat milk automatic production line equipment

View similar products

Label List

Product inquiry

Note: Please leave your mobile phone and email address, our professionals will contact you as soon as possible!