Share

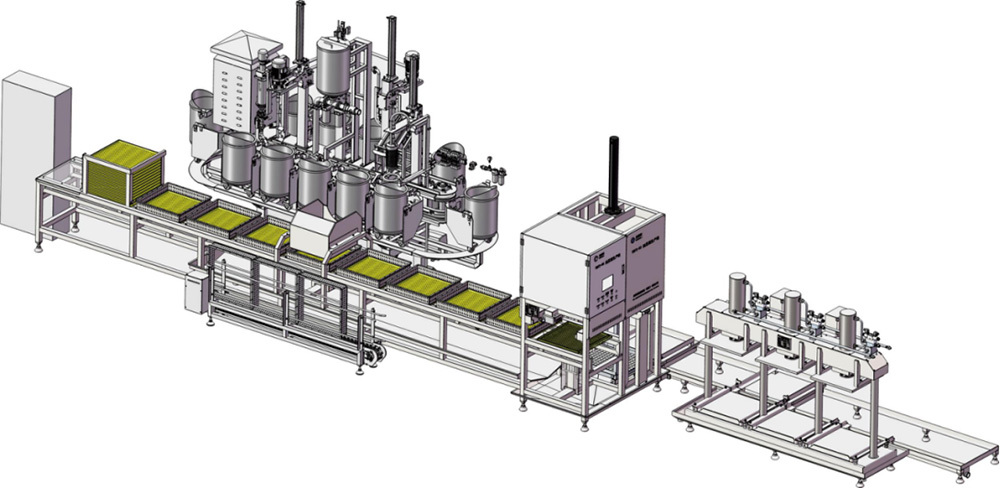

Oil tofu automatic production line equipment

View similar products

Label List

- Product Description

-

I. Introduction of Oil Tofu Automatic Production Line Equipment

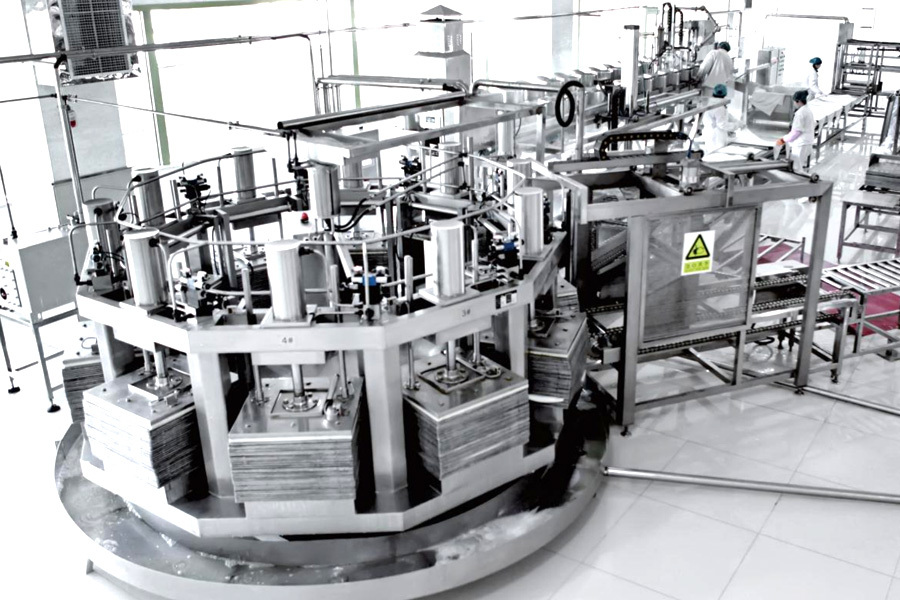

This fully automated louver production line is an efficient production solution that covers the entire process from raw material handling to finished product packaging. It is mainly composed of several key parts: the soaking system for soaking beans. The grinding system for grinding beans to extract slurry. The separation system for separating soybean dregs and soybean milk. The boiling system for boiling soybean milk, and the final point pulp. Pressing. Cutting and packaging system. The dry bean processing capacity of this system is between 400 and 600kg per hour. With the high-efficiency coagulation equipment of Yongsmooth Food Machinery, it can produce natural standard tofu of 200 to 300 plates per hour.

Oiled tofu is rich in high-quality protein and has high nutritional value; tofu skin contains a lot of lecithin to prevent hardening of blood vessels, prevent cardiovascular diseases, and protect the heart; and contains a variety of minerals, supplement calcium, and prevent calcium deficiency. Osteoporosis, promote bone development, is extremely beneficial to the bone growth of children and the elderly.

Using PLC and HMI technology to reduce labor costs and achieve capacity optimization]

The oil tofu production equipment provided by Konderi Intelligent Technology Co., Ltd. is known for its user-friendliness and aims to simplify the production process of oil tofu. With our technology, it's easy to get started even without a sophisticated technical background or specially trained staff. All the staff need to do is some basic operations, such as placing the tofu mold on the press, preparing the bean brain and other simple steps to produce high-quality oil tofu.

In addition, our oil tofu production line is designed with ease of maintenance and is equipped with PLC (programmable logic controller) and HMI (human machine interface) remote upgrade functions. This means that through a simple operator interface, just like operating on a tablet, you can easily control the entire oil tofu production process. Kondeli is committed to using PLC and HMI technology to provide you with efficient and intelligent oil tofu production solutions.

[One click, tofu production is no longer difficult]]

Konderi Intelligent Technology ensures the consistency and excellence of product quality by introducing advanced intelligent technology to manage every link and detail of tofu production. The operation interface we designed is very user-friendly. Even inexperienced personnel can skillfully operate the equipment to make tofu after receiving just three days of training. With our equipment, the production of oil tofu has become simple and easy, and it is no longer a technical problem.

We teach you how to easily make good oil tofu]

If you have never made oil tofu in the past and want to enter the tofu industry; Please feel free to give it to us when you produce your first piece of oil tofu! We provide complete production equipment as well as technology transfer. You no longer need to spend several years learning how to make oil tofu, wasting your precious time and thus failing to successfully grasp the market opportunities. We have teachers who have been deeply engaged in the bean products industry for more than 20 years to teach you how to make oil tofu. With the fastest time to join the tofu industry, the production of high quality tofu, will be the key to your investment success!

1. Pre-processing system

1. Mainly includes dry bean conveying system and soaking system. The soaking system is mainly based on the subsequent product type and output to select different sizes and quantities of bubble bean barrels, production line characteristics.

2. The machinery produced by Kangdeli Intelligent Technology Co., Ltd. has quantitative equipment, which can accurately weigh dry beans to ensure product stability;

3. Timing and automatic drainage, saving labor costs while ensuring high-level soaking beans;

4. Timing and automatic beans, to ensure that all soybeans can be evenly soaked, improve the extraction rate of soybean protein, water power failure, water shortage alarm, to solve potential safety hazards;

5. We pay great attention to the soaking quality of soybeans at the beginning of each step, automatically adjust the water temperature, fully automated, and save labor costs.

2. Wet bean quantitative lifting system

1. It integrates the functions of wet bean draining, cleaning and quantitative conveying, and the integrated equipment saves the floor space and reduces the equipment cost;

2. The equipment uses the principle of screw conveyor to ensure the stability of the conveying rate of soybeans

3. Low energy consumption, strong adaptability, reasonable equipment size design, low requirements for plant height.

3. Pulping system

1. Wheel refiner

1. The structure of the grinding wheel is dense, imitates the traditional stone grinding process, and produces less heat;

2. Special grinding method can prevent excessive heating of protein denaturation in advance;

3. Soybeans are fully broken by grinding between the upper and lower grinding pieces, so that the protein in them can be fully mixed with water and extracted.

4. Slagging system

1. The centrifuge produced by Kangdeli has a good slag removal effect, with low moisture content and high protein extraction rate.

2. Easy to clean, can access CIP, through the CIP to clean the centrifuge can effectively reduce labor costs

3. You can choose different types, and the machine is suitable for various production scenarios, and can ensure long-term high-intensity operation without problems

4. There is a stainless steel filter screen inside, which has a long service life, and the filter screen can guarantee that it does not need to be replaced within 1 year.

5. Boiling pulp system

1. Menu-style selection of boiling pulp mode, automatic control of steam and pulp mixing ratio; physical defoaming. No need to use defoaming agent;

2. Soybean milk (bean dregs are separated after being ground with water). Bean paste (bean dregs are not separated after being ground with water) can be boiled;

3. The bad gas can be discharged during the cooking process to ensure safety and ensure that the internal pressure is within a safe range;

4. CIP cleaning to ensure food hygiene and safety, optional heat recovery system.

6, cooked pulp screen

Features:

1. It is used for filtering and removing coarse particles caused by thermal expansion of soybean fiber in cooked pulp, so as to improve the yield and fineness of subsequent products.

2. Use the hanging basket mechanism to drive the flat screen to reciprocate. There is a slurry storage box under the flat screen, a built-in heating and heat preservation device, and a funnel at the top, which is conducive to the discharge of filtered coarse slurry residue. Filter screens of different materials and mesh numbers can be selected according to the use requirements.

7. Oil tofu production line

1. Compact structure, small footprint, convenient and flexible operation.

2. The thickness of oil tofu can be adjusted according to different products, the bean flower is complete and uniform, and the thickness is consistent.

3. High brain, prevent bean brain broken, improve the production rate.

4. PLC fully automatic mixing water pulp, fully automatic point pulp.

5. The whole line is equipped with a yellow slurry water collection tank, which can maintain the production environment in the production process, which is conducive to the management of the production site.

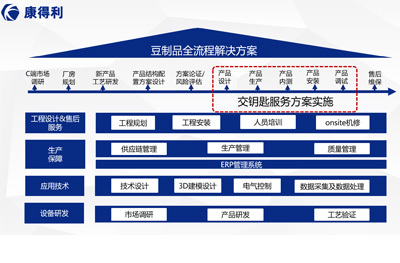

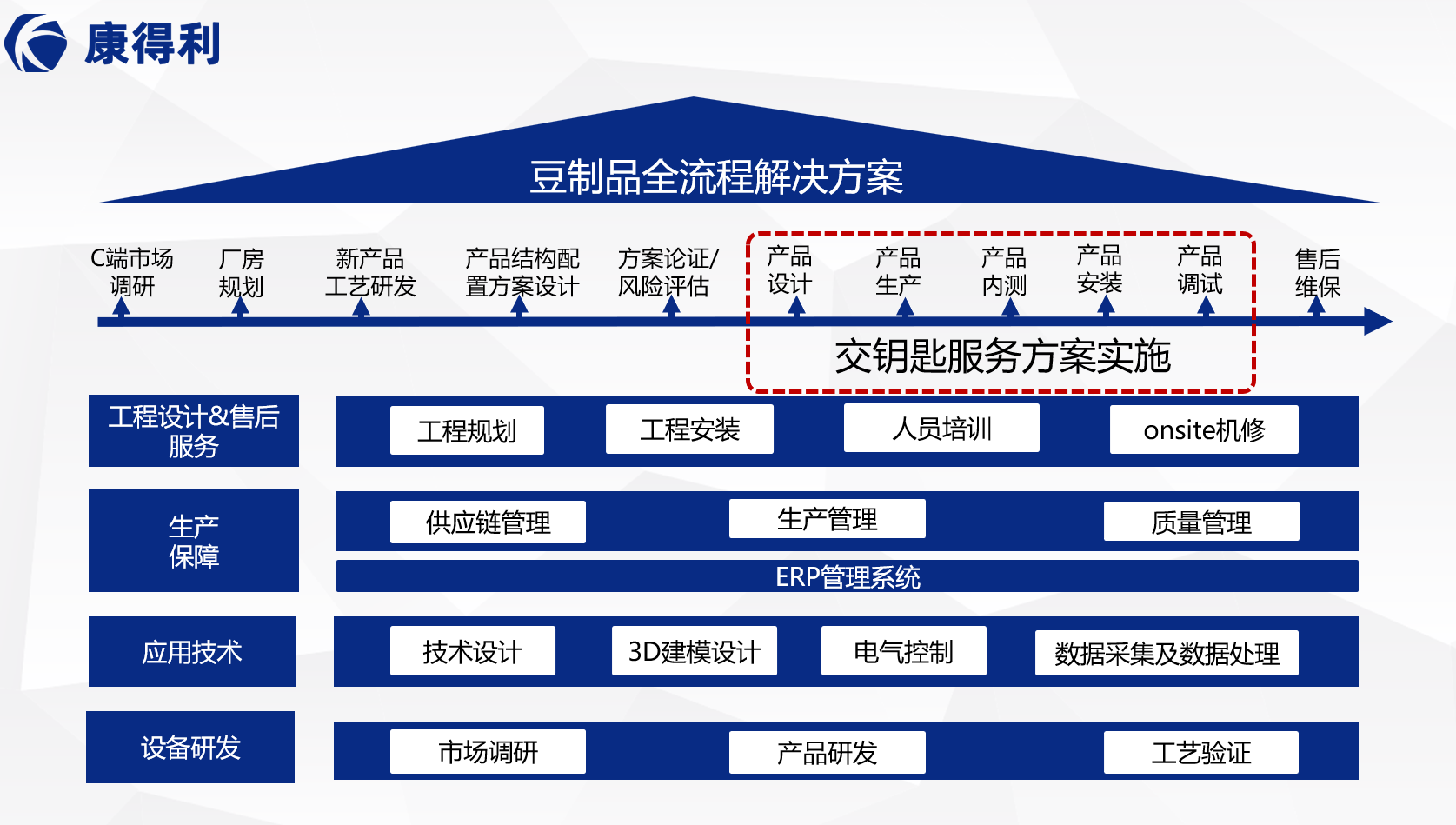

Full process solution

We have professional marketing. R & D. Pre-sales. After-sales team, to provide you with professional bean products full process solutions.

Service Consulting

Kondley Intelligent Technology provides 24-hour online consultation, cooperates with engineers, solves customer problems through remote operation, saves round-trip time and labor costs, and can quickly solve customer problems. In addition, for food equipment companies that have just started a business or expanded their factories, our engineers will visit the company's site to help you plan the layout. In the past 28 years, we have established good cooperation with global customers such as Sweden/Malaysia/USA/Indonesia/Canada, and passed on the technical know-how of producing soybean milk and tofu to our customers. We are committed to being the leading solution provider.

Consulting Services

Please contact us and we will provide you with further consulting services.

Oil tofu automatic production line equipment

View similar products

Label List

Product inquiry

Note: Please leave your mobile phone and email address, our professionals will contact you as soon as possible!